At WiseGEEK, we're committed to delivering accurate, trustworthy information. Our expert-authored content is rigorously fact-checked and sourced from credible authorities. Discover how we uphold the highest standards in providing you with reliable knowledge.

What is Polycarbonate Sheeting?

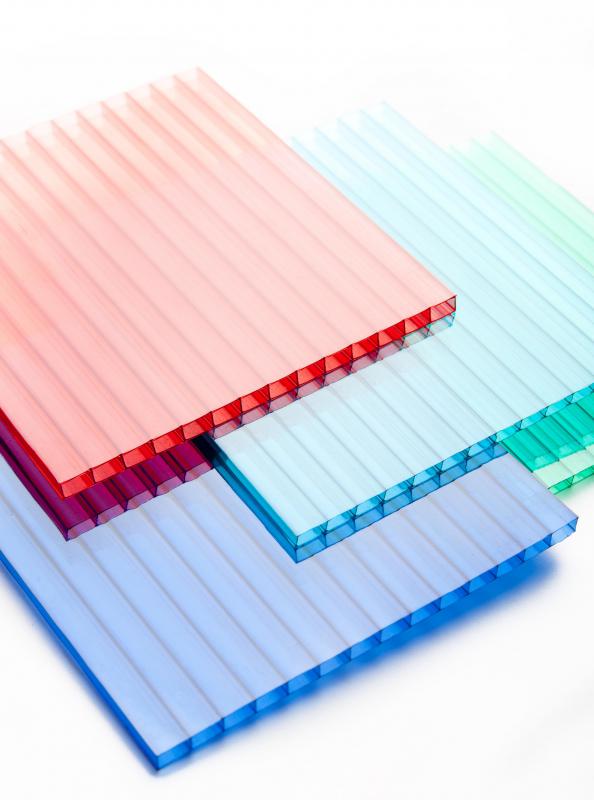

Polycarbonate sheeting is a type of building material used to replace glass in a variety of applications. Made from thermoplastic composites, polycarbonate sheeting typically offers greater flexibility and shatter-resistance than acrylics or plexiglass. It comes in sheets that can vary in thickness from less than an inch to several inches thick. This product is often referred to by the brand names Lexan® or Makrolon®, which are among the most popular brands of polycarbonate sheeting.

This material may be used as an alternative to glass in doors and windows. It's also popular for shower and pool enclosures, as well as on balconies and in greenhouses. Polycarbonate sheets may be found in sporting areas, where it is used to protect spectators from flying balls or hockey pucks. It's also used to make compact discs and eyeglass lenses.

Polycarbonate sheeting provides a great deal of options to installers and designers in terms of how it can be used. It can be held in place using screws, and may be used with specialty support poles designed to hold larger sheets. It can also be joined to other materials using epoxy or silicone, and can even be welded. Silicone sealant is often used to seal or caulk polycarbonate sheeting along its seams or joints.

One of the primary advantages to this type of sheeting is its high strength to weight ratio. Compared to glass, polycarbonate sheeting is very light, but also highly resistant to shattering and damage. This shatter resistance makes this material much safer than glass, which could lead to injuries if broken. Polycarbonate sheeting also acts as a sound barrier, and may help control UV-light infiltration. It also offers a high degree of flexibility, making it easy to form each sheet into the desired shape.

Compared to some other composite plastic sheeting products, polycarbonate sheeting tends to be fairly expensive. It may also be susceptible to damage or failure if exposed to high temperatures. Like other plastic sheet goods, polycarbonate sheeting may suffer surface scratches due to a variety of factors. These scratches can be removed using special polishes or cleaning products, though some may be permanent. Over time, excess scratching can cause the surface to appear dull, and may reduce visibility and light transmittance.

Polycarbonate sheeting also poses some limitations in the food industry. It typically contains BPAs, which many suspect may be linked to certain health concerns. This means that polycarbonate may not be used in many food storage or restaurant applications.

AS FEATURED ON:

AS FEATURED ON:

Discuss this Article

Post your comments