At WiseGEEK, we're committed to delivering accurate, trustworthy information. Our expert-authored content is rigorously fact-checked and sourced from credible authorities. Discover how we uphold the highest standards in providing you with reliable knowledge.

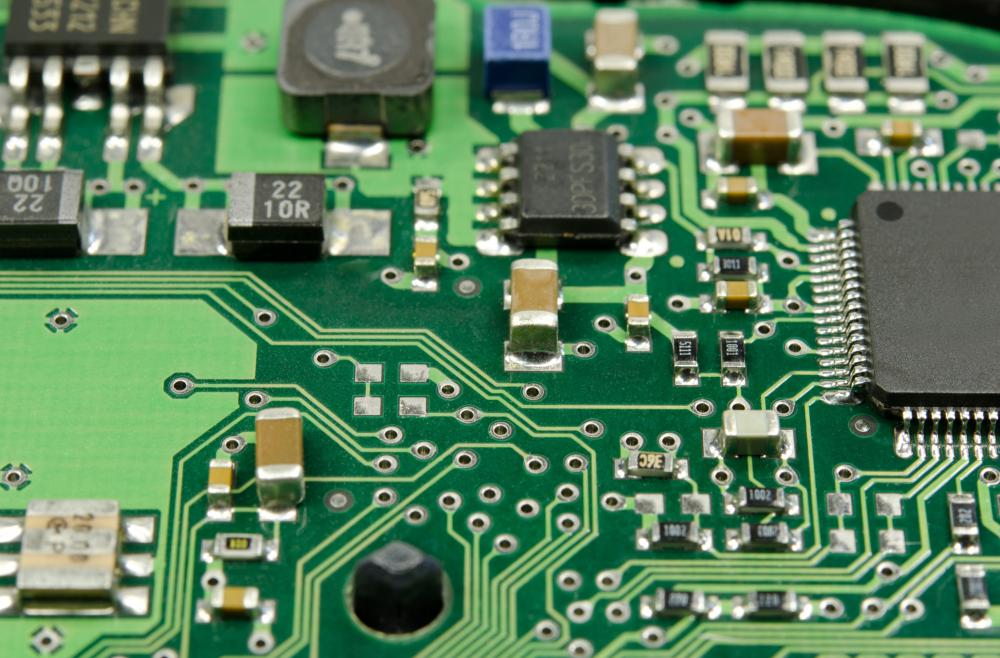

What Are the Best Tips for Circuit Board Wiring?

The best tips for circuit board wiring include choosing quality raw materials, using properly adjusted production machines, and assuring a quality board with thorough testing processes. Production areas should also be designed to be free from damaging static electricity by strategically grounding the immediate work area. Any circuit board wiring defects or issues should be pinpointed immediately; an engineer must research and repair a poorly drawn circuit schematic to continue production.

Circuit board wiring is commonly made from a mixture of flux and solder, also known as solder paste. Before a circuit is created across a board's surface, the flux and solder mixture must be made at the proper ratio using quality raw materials; engineers will commonly specify the ratio in their schematics since it can differ between each device the board will be controlling. Solder paste must be the correct viscosity to be applied across the board, or PCB. Similar to a screen printing process, the circuit board wiring is generated by forcing the paste through a screen mesh and onto the PCB.

Modern technology uses multiple production machines to create circuit board wiring since the PCB and components are extremely tiny. These machines must be adjusted for correct temperature and alignment while working with a PCB. For example, the solder paste must be melted within a reflow oven to permanently adhere electronic components to the circuit pathways. If the oven's internal temperature is too hot, the PCB will be damaged and will require either a rebuild or will simply be thrown out as waste.

Machines also place the electronic components on the board's wiring pathways; this production machine must be calibrated and aligned accurately so that it will choose the correct component out of the inventory supply, as well as place it precisely on the specified solder paste pad. Improperly adjusted component placing machines will produce circuit board wiring with multiple component errors. These inaccuracies can cause the PCB to work incorrectly and possibly overheat.

Even with the best production machines, circuit board wiring may still be flawed after the final assembly process is completed. This is why it is imperative to have a thorough testing process; workers should have an area set aside so that each board can be powered up and operated. For example, a testing process can include applying power and switching each function on, such as evaluating each button on a cell phone keypad.

Static electricity is a constant danger in production facilities. Each work area should have grounding mats that allow an employee to attach themselves to the neutral ground through wrist or ankle straps. An electrical surge across a PCB from static electricity can easily damage the internal wiring.

AS FEATURED ON:

AS FEATURED ON:

Discuss this Article

Post your comments